X360009 XRAY XB4 2021 - 4WD 1/10 ELECTRIC OFF-ROAD CAR

XRAY XB4 2021 - 4WD 1/10 ELECTRIC OFF-ROAD CAR

XRAY XB4 2021 All-new Features:

- Next generation of the multi-time World Champion XB4 platform

- Available in Carpet and Dirt Editions ready for high or low track conditions

- All-new front & rear bulkheads with Horizontal Split Design (HS)

- All-new front and rear diff height adjustment

- All-new central drivetrain angle and height adjustment

- Longer front and rear central drive shafts and shortened pinion gears for improved drivetrain efficiency

- All-new Multi-Adjustable Slipper Clutch with independently adjustable front/rear slippage

- New 2mm chassis redesigned to accommodate all the new components

- All-new front & rear suspension holders with extra wide range of set-up adjustments

- Revised front & rear shock towers with closer shock positions for finer adjustment

- Updated front shock absorber bodies and shafts shortened by 2mm for increased stability and corner speed

- All-new tweak-free Quick Battery Holder featuring smart height adjustment

- New rear body mount with a more frontward position to accommodate the new bodies

- All-new servo saver stands to accommodate the new front Horizontal Split Bulkhead (HS)

- Two new Gamma body styles designed to enhance the handling characteristics of the Carpet and Dirt Edition kits

XRAY XB4 World Champions.

At the World’s most competitive off-road race – the IFMAR World Championship, it was XRAY’s Bruno Coelho and Daniel Kobbevik securing another World Champion and Junior Champion titles for the XB4 platform.

XRAY XB4 – the 4x World Champion 1/10 off-road 4WD car that will bring you to the Winners’ Circle.

XRAY XB4 Made in Europe.

Engineered and manufactured in-house at the XRAY factory located in Slovakia, Europe, the XB4 is a fantastic demonstration of XRAY’s attention to detail in all of its products. The XB4 is created by XRAY’s design staff using premium European materials and sophisticated German and Swiss machines.

XRAY XB4 USA Champion.

XRAY’s Ty Tessmann achieved the first ROAR National Championship for the XB4. Tested and successfully run in the highest competition races now you can enjoy the winning platform.

XRAY XB4 Concept.

The XB4 is typical XRAY: ultimate professional, high-competition RC car for the most demanding racers, developed with attention to the finest detail, and backed by premium service & support…a luxury masterpiece.

- Functionality

- Highest quality

- Highest performance

- Easy to service

- Easy to set-up

- Long wearing

- Strength and durability

- Ingenuity

- Smart design

- Premium materials

XRAY XB4 Passion.

The XRAY XB4 has been one of our most successful platforms, one that the racing and R&D teams continue to improve year after year as they work to create the finest and best-performing 4WD off-road car in the world.

XRAY XB4 European Champions.

With ongoing development of the XB4 platform, Team XRAY continues to win at the highest competition levels including the European Championship. The XB4 is a multi-time European Champion as well the European Junior Champion.

Heritage.

XRAY has been a driving force in the 1/10 off-road car racing scene since the release of the first XB4. Continuous development and evolution of the XRAY product line has led to ever-increasing performance. The craftsmanship, durability, and performance of XRAY kits have become legendary. Be part of the family, live the heritage.

XRAY XB4 EOS Champions.

XRAY XB4 has been one of the most successful 4WD off-road cars in the EOS racing series, winning 4 overall season titles. In 2019 it was again Bruno Coelho winning the 4WD Modified Class Championship in one of the most competitive race series in the world.

High Performance.

Since the release of the first XB4 in 2012, XRAY has been a driving force in the 1/10 electric off-road car racing scene. Continuous development and evolution of the XRAY product line has led to ever-increasing performance to provide you the with the highest performance 4WD buggy.

XRAY XB4 Chassis.

The chassis is updated to accommodate all the new features including the new front and rear bulkheads, the new suspension holders and the tweak-free Quick Battery Holders.

The chassis is an important component that contributes to the XB4’s handling characteristics. The chassis dimensions and flex characteristics are selected for the best blend of stability, traction and steering. The chassis is machined for extra clearance under the bulkheads to accommodate the new diff height adjustment feature.

CNC-machined from high-quality Swiss 2mm 7075 T6 aluminum, the chassis is strategically machined in low-stress areas to make it as light as possible without affecting strength or rigidity; and it is additionally black-coated for increased lifespan.

XRAY XB4 Bulkheads.

All-new front & rear bulkheads feature a horizontal split design (HS) to retain easy diff access while adding the valuable new diff height adjustment. The unique design of the bulkheads uses an inline bushing to alter the alignment and height of the bevel drive gear. In addition to accommodating the new diff height adjustments, it also allows the front central driveshaft to operate with a reduced angle for less friction and wear on the CV joint components and improved driveline efficiency.

The XB4 bulkheads allow fast and easy differential access for setup changes or servicing by removing only 4 screws from the upper gear box cover while the lower section remains mounted to the chassis. This super-fast diff access is featured on both front and rear gearboxes.

The super-strong, narrow bulkheads provide the needed clearance for the redesigned suspension holders with increased set-up range possibilities.

XRAY XB4 Diff Height Adjustment.

All-new front & rear HS bulkheads allow for a new diff height adjustment using eccentric bushings. In the front gearbox, the diff height has 3 different settings. The rear differential can be adjusted through a 5mm range. The diff height adjustment is a vital set-up capability that allows quick set-up adaption for either Carpet or Dirt tracks.

Carpet edition uses a lower ride height and the upper differential position to keep the drive shafts level.

Dirt edition typically uses a taller ride height and a lower differential position to keep the drive shafts level.

XRAY XB4 Diff Height Adjustment.

XRAY XB4 Central Drive Train.

The new design of the HS bulkhead with the inline bushing for the bevel drive gear creates a more linear orientation for the front center drive shaft to reduce the CV joint angle for increased driveline efficiency and decreased friction and wear. The height and angle of the rear center drive shaft is also adjustable depending on the height adjustment of the differential.

Front - there are 3 different angle configurations for adjustment of the front drive train.

Rear - there are 6 different height configurations for adjustment of the rear drive train.

XRAY XB4 Diff Gears.

The new pinion gear is shorter to allow the drive shafts to move the CV joint closer to the differential to improve drive train efficiency.

Both crown gear and pinion gear are CNC-machined from HUDY Spring Steel and are ultra-hardened making them very strong and reliable with a longer life span. The split crown gear allows for a simpler exchange to optional gears without requiring a rebuild of the internal diff assembly and results in significantly lower rotating mass and improves the serviceability.

To improve the gear engagement both crown gear and pinion gear have more teeth and geometry that results in smoother engagement and increased efficiency.

XRAY XB4 Center Driveshafts.

All-new longer front and rear central driveshafts integrate with the new gearbox dimensions and move the CV joint closer to the differential to improve drive train efficiency.

XB4 constant velocity drive shafts are manufactured from world-renowned HUDY Spring Steel™ and feature 2.5mm drive pins for maximum drivetrain efficiency. The drive shafts are some of the world‘s thinnest yet most durable drive shafts used in electric off-road cars. Hardened with a proprietary hardening process, the drive shafts provide unbeatable lifespan and reliability.

XRAY XB4 Slipper Clutch.

The unique Multi-Adjustable Slipper Clutch – MSC, with independently adjustable front and/or rear slippage via different slipper pads and clutch plates of different diameter, ensures more efficient and more consistent clutch operation to generate faster acceleration and less wheel spin.

For improved performance there are two different pad materials; yellow SLS pads with higher slippage and black medium hardness with less slippage. The slippage ratio between front and rear tires can be adjusted independently depending on the type of the track, tires and racing style.

The Multi-Adjustable Slipper Clutch is included in Carpet Edition.

XRAY XB4 Slipper Clutch Adjustments.

XRAY XB4 Central Gear Differential.

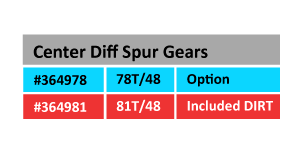

The central differential is now included in the Dirt Edition. The gear diff shares the same universal diff case and internal parts found in the front/rear differentials.

The maintenance-free, super-smooth gear diff has greater internal oil volume to increase consistency of the diff action and includes a composite case and cover with internal satellite gears that are precision-molded from special XRAY-developed graphite composite material, ensuring a long lifespan and super-smooth, efficient operation.

The differential outdrives are designed for use with 2.5mm driveshaft pins. The gear diff set includes an 81T spur gear and a 78T spur gear is available as an option.

The central differential is recommended for use on clay, bumpy Astro and low-traction tracks to increase traction.

I.S.S.™ Suspension Holders.

All-new front & rear suspension holders are redesigned along with the new HS bulkheads for an expanded range of set-up adjustments.

The rear suspension holders can be installed in upward or downward orientations, resulting in additional roll center locations for the inner hinge pins.

The downward orientation of the suspension holder is used primarily for Dirt tracks.

The upward orientation of the suspension holder is used primarily for Carpet tracks.

The suspension holders allow use of both the long or standard suspension arm configurations.

Machined from premium Swiss 7075 T6 aluminum and black coated.

XRAY XB4 Suspension Arms.

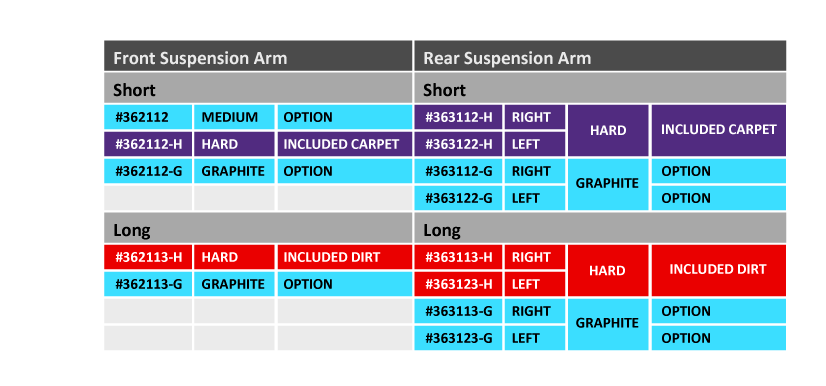

Carpet and Dirt editions include different suspension arms selected for their expected track conditions.

The Carpet edition uses the short suspension arms, while the Dirt edition includes the long suspension arms.

Rear suspension arms accommodate the multi-adjustable uprights. The outer pivot of each arm uses small screws to secure the hinge pins and prevent separation in a crash. This floating hinge pin reduces suspension bind.

The suspension arm itself is rigid enough to provide a responsive feel, yet soft enough for extreme durability. The exclusive composite mixtures used for the suspension arms offer a perfect balance between reliability & performance.

There are two different suspension arms available: hard and graphite, each suitable for particular track conditions.

XRAY XB4 Shock Towers.

All-new front & rear shock towers are redesigned to accommodate the Horizontal Split Bulkheads (HS) and feature denser upper shock mount positions for more precise set-up adjustments.

The rear shock tower features extra roll center positions for precise set-up adjustment and extra wing mounting positions.

Both front & rear shock towers are machined from premium-grade graphite and are lightweight & strong, with multiple shock positions and roll center adjustment positions.

XRAY XB4 Shocks.

The front shock absorber bodies and shock shafts are shorter by 2mm. Combined with the new shock towers and suspension geometry, these changes increase stability and improve cornering speeds.

The big-bore shocks are membrane free, but still allow for easy, consistent building and rebound control using a bleed-screw shock cap design.

The aluminum body and lower cap are all machined from premium Swiss 7075 T6 aluminum.

The shock shafts are machined from special steel material, precision hand-ground for maximum smooth operation, and additionally hardened for increased lifespan.

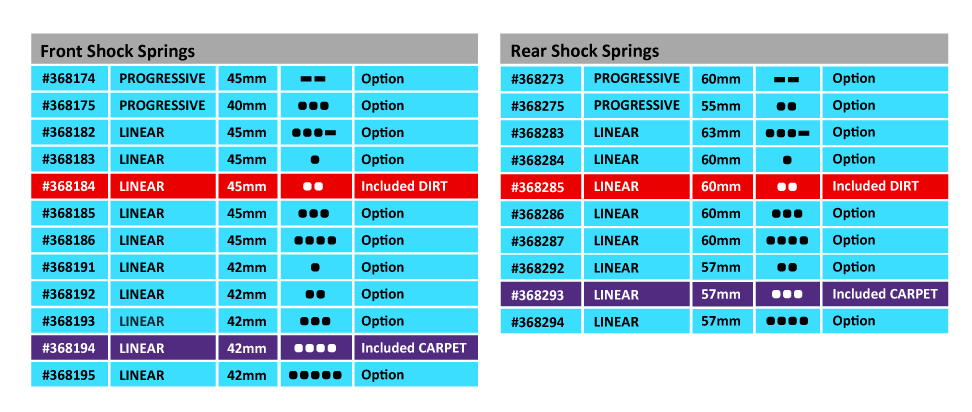

XRAY XB4 Shock Springs.

Both Carpet and Dirt edition include shock springs selected for the specific track conditions.

There are two types of springs offered:

• Linear – The spring rate is constant during the entire spring compression. Springs with different linear spring rates are available as optional tuning parts.

• Progressive - The main advantage & benefit of progressive springs is that as the car initially enters the corner the springs work like softer springs to provide maximum traction. As the chassis begins to roll in the middle of the corner, the spring rate progressively increases until it works like a stiffer spring which allows the car to maintain maximum cornering speed.

XB4 springs, like all other XRAY springs, are manually measured, selected, and matched into pairs to guarantee precisely equal length and damping characteristics.

Each spring is laser-engraved with stripes to indicate the firmness, the more strips, the stiffer the spring.

Battery Holder.

All-new tweak-free Quick Battery Holder allows for easy retainer height adjustment for more convenient battery mounting. The entire system is intended to reduce the effects of the battery and holder on chassis flex, making the XB4 more predictable and easier to drive.

The battery holder is universal for both Dirt and Carpet edition.

XRAY XB4 Side Guards.

Side guards are redesigned to accommodate the all-new Quick Battery Holder.

The side guards allow the servo mount to be connected to avoid any unwanted negative flex coming from the servo in very high traction conditions.

Tough composite side guards perfectly fit the chassis to seal against dirt and protect from side impacts.

Molded from a hard composite material, the side guards are an important part of the chassis flex adjustment for the majority of track conditions. For very-low-traction tracks, optional medium stiffness side guards are available.

To improve protection against dust, Velcro® double-sided tape is included to ensure a perfect seal of the body to the side guards, and to reduce the noise level of the running car.

XRAY XB4 Body Posts.

All-new rear body mount with more frontward position and updated to fit the new rear Horizontal Split Bulkhead (HS) and the new body. The shape of the holder allows for super easy access to the screws on the upper part of the bulkhead. Machined from premium graphite material.

Beefy 6mm thick body posts are made from a special composite material for maximum strength. The body supports are rounded to have a better fit and provide better support for the car body.

XRAY XB4 Steering System.

The dual arm steering system is simple yet effective, and features an easily adjustable integrated servo saver. Ackermann is easily adjusted by quickly changing the steering link mounting positions on the steering plate.

Bump steer is adjusted for more aggression by inserting a shim between the steering block and steering linkage.

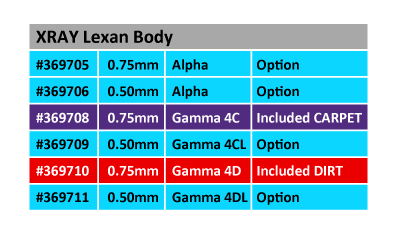

XRAY XB4 High Traction Body.

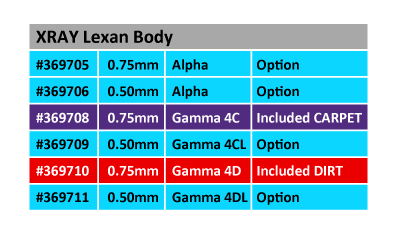

The XB4’21 Carpet and Dirt Editions each feature new specifically designed XRAY Gamma bodies with super-smooth airflow and revised downforce characteristics fine-tuned for their intended conditions.

The Carpet edition of the all-new Gamma body is designed especially for high traction conditions and improves the stability in the fast corners, chicanes and improves rotation in tight corners.

The Gamma Carpet body is also available in lightweight version.

XRAY XB4 Low Traction Body.

The Dirt edition of the all-new XRAY XB4 Gamma body is designed for low traction conditions. The all-new design improves the stability and increases traction.

The Gamma Dirt body is also available in lightweight version.

XRAY XB4 Rear Wing.

The Carpet and Dirt Editions of the XB4 each feature and individually paired wing to work with their particular body. Made from strong Lexan™ material, the wing is supported on the wing mounts by extra flat shims to better support and extend the life of the wing.

Various wing designs in different thickness are available separately. The thicker wing gives higher traction and stability but gives reduced steering.

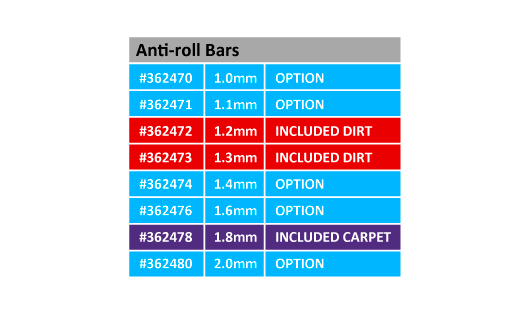

XRAY XB4 Anti-roll Bars.

Both Carpet and Dirt edition include anti-roll bars selected for their specific track conditions.

Anti-roll bars are manufactured from special spring steel material and are used to stabilize the front & rear ends of the car. The roll bars are easily mounted to the diff cases and can be adjusted with the linkages.

Front & rear anti-roll bars are interchangeable since they have same design and shape. The thickness of each anti-roll bar is laser-engraved for easy identification. Anti-roll bar wires of different thickness are available separately for fine-tuning.

XRAY XB4 Multi-Flex™.

The XB4 incorporates the innovative Multi-Flex™ adjustment technology, which allows tuning of chassis flex for different track conditions.

Regardless of whether the track has low, medium, or super-high traction, chassis flex can be adjusted to suit track conditions to gain a competitive advantage.

XRAY XB4 Chassis Brace.

The optional front graphite chassis T-Brace is designed to increase front stability on high traction tracks and makes the car more predictable and easier to drive.

The rear graphite chassis brace is installed on the lower composite brace connected directly to the chassis. The brace reinforces the rear of the car and generates more stability while increasing traction.

The chassis braces are a vital part of the Multi-Flex™ adjustability.

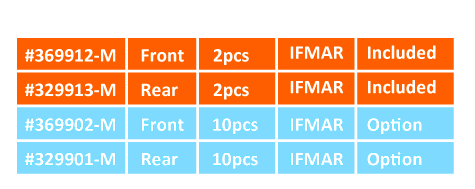

XRAY XB4 Wheels.

The included wheels are IFMAR standardized with the new wheel hex offset. The wheels feature a redesigned countersunk center area to allow the wheel nut to sit deeper in the wheel.

The wheels are perfect for high-competition racing. They feature internal reinforcement ribs to provide stability and resist deformation, yet they are made from a flexible material to provide durability and withstand impacts.

The side of the wheel is aerodynamic for maximum performance. The wheels were designed to provide maximum traction.

The wheels feature a 12mm internal hex.

XRAY Instruction Manual.

The Instruction manual is universal for both Carpet and Dirt edition and features a list of any important optional parts suggested for fine set-up adjustments.

XRAY Instruction Manuals have become the industry standard, being simply the best manuals you will ever get with an RC model car. Whether you are a first-time builder or an experienced racer, all the instructions are straight-forward and easy to understand. The full-color instruction manual contains large 3D illustrations that show all assembly details in the clearest possible way.

Download the new Instruction manual here: XB4´21 Instruction Manual

Philosophy.

At the heart of XRAY's philosophy is a firm commitment to perfection in engineering, design, performance and support… all made possible by state-of-the-art in-house manufacturing. The XB4 is the epitome of perfection that is typical for XRAY.

Dipl. Eng. Juraj Hudy

XRAY Chief Designer

Champion.

From national titles around the world… through EOS Champion titles… all the way to the European, Asian, and USA Championship titles… and the recent World Champion titles, the XB4 has an extensive and strong history of victories to support the winning heritage of the XRAY XB4 platform.

Commitment.

“Being part of the R&D team, I know how much time, energy, and effort is put into developing all of our cars. Chasing perfection is a never-ending process, and as such we strive to bring you an improved & better-handling XB4. You will be amazed by the handling & reliability improvements of the new XB4, which will help bring you to the Winners’ Circle.”

Martin Bayer

XRAY Factory Team driver

European Champion

Designing & Making of XB4.

Read the exclusive story about the designing and making of the XRAY XB4.

Development.

Successful development of the XB4 – like all other XRAY platforms – would not have been possible without the involvement of the entire racing team constantly working to test new ideas, prototypes, and improvements.

Perfection.

Designed in virtual reality using the world's most sophisticated CAD tools, and manufactured using the world's best machining and molding machinery, the XB4 achieves a level of perfection in all details that is second to none.

Some information shown below may include details from previous kits,

and it may vary slightly from current kit specifications.

Gear Differential.

The front and rear gear differential features a split design of the cover and crown gear. The differential case has greater internal oil volume to increase consistency of the diff action, yet it is significantly narrower and to move the rotating weight closer to the centerline.

The super-smooth, low maintenance gear diff includes a composite case and cover with internal satellite gears that are precision-molded from special XRAY-developed graphite composite material, ensuring a long lifespan and super-smooth, efficient operation.

Gear differential features all-new diff-outdrives designed for use with 2.5mm pin.

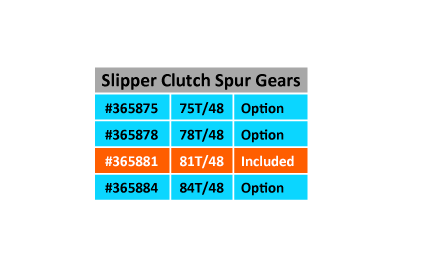

Spur Gear.

Precision-molded spur gears are made from XRAY's exclusive secret blend of composite material, allowing the gear to run true yet be robust enough to handle high-performance brushless motors. The spur gears are designed to have the lowest possible weight while staying strong and light. Each gear is stamped with the tooth number for easy identification.

The XB4 is equipped with an 81T spur gear which suits the majority of tracks. For additional tuning, optional 75T, 78T, 84T and 87T spur gears are available.

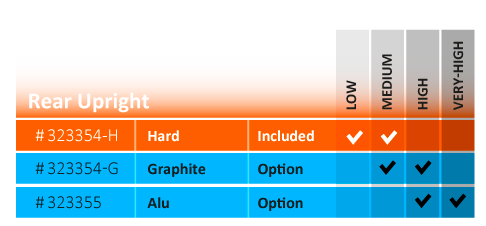

Rear Uprights.

The multi-adjustable rear uprights allow for super fine tuning of the suspension geometry.

The upper roll center is adjusted at the camber linkage via shims (up/down & in/out), while the lower roll center is adjustable via eccentric inserts for 9 different positions (up/down & in/out).

The multi-function uprights have the upper roll center position in the middle of the axis of the driveshaft joint to help generate more traction and increase stability.

There are three different uprights available: hard (included), graphite (optional), and aluminum (optional), each suitable for particular track conditions.

Motor Mount.

The motor mounting plate features a shape for easier access to the pinion gear set screw. The inner motor screw is recessed into the mount for improved clearance around the center spur gear.

The motor is connected to an eccentric mounting plate, with the assembly then inserted into an integrated motor holder/drivetrain support. The design allows quick & easy motor rotation to adjust gear mesh, and still securely holds the motor plate using only a single screw.

To ensure the motor will not loosen in a serious crash or due to insufficient tightening, the motor plate has a bayonet mounting system which prevents it from being dislodged from the motor holder. By rotating the motor mount plate to the opposite direction, the motor can be quickly removed from the vehicle.

Removing the motor or adjusting the gear mesh is easy and fast, with changes possible in only a few seconds.

Motor Bulkhead.

The lowered motor bulkhead reduced the CG of the motor and central slipper clutch/diff, improving cornering speed and stability.

Machined from the premium Swiss 7075 T6, the motor bulkhead is strong and lightweight.

Central Bulkhead.

The central assembly features a new upper top deck to match new layout of the motor mount and central bulkheads on the chassis plate. The entire assembly is more compact with weight placed as close to the chassis centerline as possible. The new upper deck also fits the optional central differential’s new case design and dimensions.

The graphite central upper deck holds ball-bearings in the motor mount and bulkhead assembly, while the upper deck allows easy access for slipper clutch adjustment.

Suspension.

The correct suspension geometry is one of the most important features of any RC model car, while at the same time being one of the most difficult and challenging features for a designer.

The suspension is always a mixture of:

• design and shape of individual suspension parts

• flex and hardness

• materials used

• mounting system

• geometry and position of mounting points of connecting parts

From the suspension arms, through the suspension blocks, to the light yet robust steering blocks, every suspension part has been specially designed for the 1/10 off-road racing platform to provide responsive racing characteristics in all conditions.

Servo Mount.

The servo mount has a more compact and stronger design. The servo mount is now secured to the side guard to eliminate any unwanted servo movement that can occur in very high traction conditions. The reduced deflection translates into more consistent and precise steering response while cornering.

Wheelbase Adjustment.

Suspension arms allow for quick & easy wheelbase adjustment. Using included 2mm shims, both front and rear suspension arms can be moved either forward or rearward to adjust weight balance depending on track conditions.

By moving the arms to the front, the balance and weight of the car are transferred more to the rear; this is recommended for medium- and high-traction conditions.

By moving the arms to the rear, the balance and weight of the car are transferred more to the front.

Steering Blocks.

The tiny yet tough steering blocks are molded from a special composite mixture for maximum strength.

Composite steering block inserts allow for very quick & easy lower roll center adjustment. With additional shims and extra inserts, fine tuning the roll center is easily achieved.

For maximum drivetrain reliability, larger 5x12 ball-bearings are used in the outer position with increased dynamic load. On the inner position, the smaller 5x10 ball-bearings are used for minimized unsprung weight.

Caster Blocks.

The 1-piece caster blocks are very lightweight, yet the construction makes them very stiff and rigid. The non-adjustable caster angle is preset to 9°. Roll center position can be quickly & easily adjusted by inserting different thickness of shims atop the caster block (between the block and the vertical ball stud).

The non-adjustable caster is preset to 9°, however the position of the adjustable eccentric bushings in the I.S.S.™ suspension holders influences the caster as well. (For example, if the eccentric bushings have the roll center in middle position, the caster angle is 9° which when added to the 9° caster block gives a total of 18° caster. The total adjustability range for caster is 16-20°.)

Optional caster blocks with 6° and 12° built-in caster angles are available for further suspension geometry adjustment.

There are four different caster blocks available: medium (optional), hard (included), graphite (optional) and aluminum (optional), each suitable for particular track conditions.

The new hard caster blocks increase stability in high-traction conditions, and help to increase cornering speed.

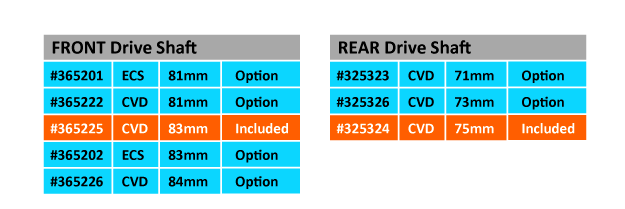

Drive Shafts.

The front and rear driveshaft lengths are updated to match the new differential width and suspension geometry; the front drive shaft is 83mm long and the rear drive shaft is 75mm long.

The safety collar on the front driveshaft secures the pin, while the ball bearing captures the pin in rear axles, both preventing the pin from coming lose during a run.

XB4 constant velocity drive shafts are manufactured from world-renowned HUDY Spring Steel™ and feature 2.5mm drive pins for maximum drivetrain efficiency. The drive shafts are some of the world‘s thinnest yet most durable drive shafts used in electric off-road cars. Hardened with a proprietary hardening process, the drive shafts provide unbeatable lifespan and reliability.

Ball-bearings.

All-new larger ball-bearing used in the rear uprights for increased reliability. The XB4 features greased ball-bearings for front steering blocks & rear uprights to increase lifespan in dusty conditions. The remaining bearings are degreased and oiled with AeroShell® Fluid 12 for maximum smoothness and long life.

A full set of high-speed ball-bearings are used throughout the drivetrain to ensure maximum efficiency.

Turnbuckles.

Shock Pistons.

Shock pistons are made from Delrin® and are molded using ultra-high precision molds. All-new 2-hole pistons (1.6mm and 1.7mm holes) are now included in the set.